MedConWms – MedCon Warehouse Management

The application of the MedCon family for the physical management of the “medical” warehouse; Warehouse Mapping, Reception in the arrival area, Transfers to the stock or Quarantine area, indication of the storage location, “Cells” management (eg Washers), Picking, Shipping, Loaners and Kit Management.

MedConWms – Main Features

The solution is part of the web-based cloud software platform named MedCon with a new set-up developed to manage the physical warehouse functionalities:

- Goods receipt of Loaners in the “Arrival zone”

- Loaners transfer from the Arrival zone to the Loaner warehouse, included the Quarantine or maintenance area for the kit to be isolated (E.g.: incomplete kit).

- Loaners transfer from the Arrival zone/Quarantine to the Loaner warehouse, with the automatic indication of the final destination area (Shelf/Bin).

- Link between PBS (Primary Business System) Pick list and equipment in order to get the Loaners pick-list.

- Equipment goods issue

- Cells (e.g. washer) management

The software MedCon already provides the following features:

- Goods receipt via Barcode-reading

- Warehouse mapping based upon different areas (Current whse, maintenance and shelves or floor stocking areas)

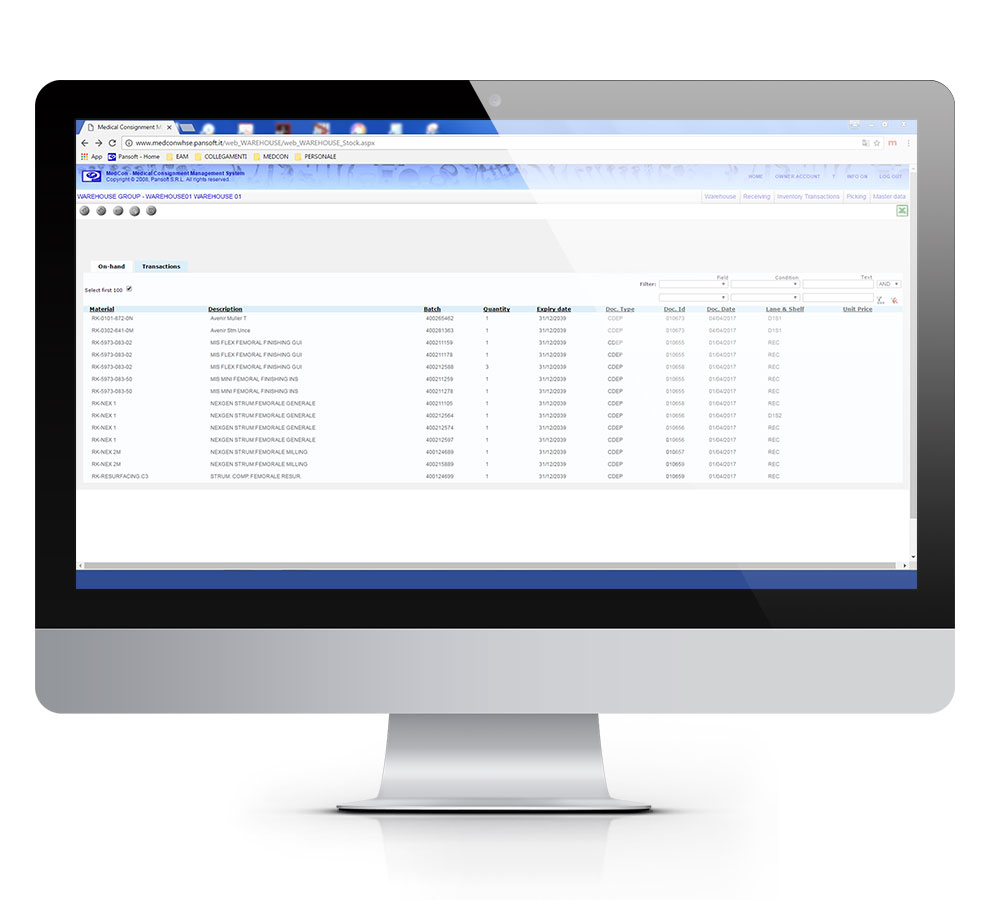

- Display functionality of inventory per shelf/bin/item/equipment

- Transfer and goods issue functionality via Barcode-reading

- It is in Cloud hence no need of particular support from IT infrastructure

Every single handling unit (box/tray) must be labeled with the following information:

- RK header

- Id. Equipment;

While it is possible to manage 1 Equipment in more than one of Handling Units (the same equipment is made up by more than 1 box), it is not possible to manage more than 1 equipment in 1 handling unit.

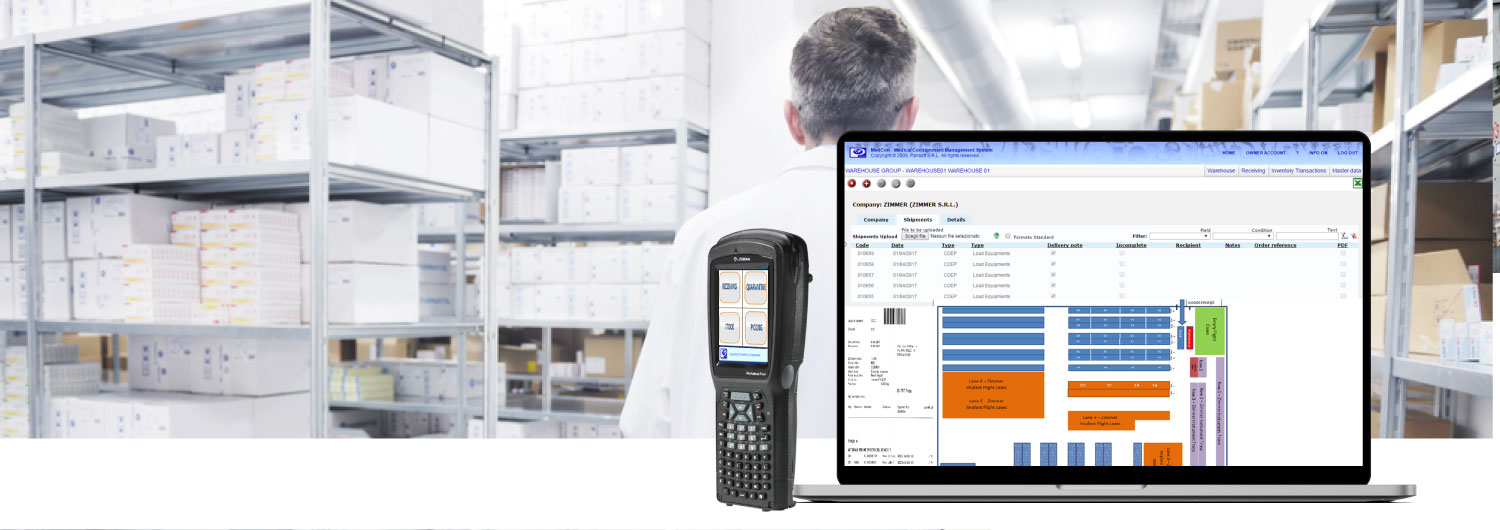

MedConWms solution involves the use of Industrial barcode reader together with a WiFi network to manage as best as possible all the warehouse operations.

HardWare set-up

Personal computer with internet access, a browser internet in order to enter Medcon and manage the following functionalities:

- Master data settings (for warehouse management)

- Warehouse mapping

- Inventory and movements analysis

- Manual posting (In case the equipment has No label)

Barcode Reader to allow also the usage of the fixed workstation to read barcodes if needed

Industrial barcode readers with operating system windows CE 6.0 or later versions with access to internet (WiFi) in order to execute the Goods receipt/Transfer/Goods issue of loaners within the warehouse.

Barcode characteristics for Equipment and warehouse areas/shelves still to be defined and verified:

- Possibility to print barcode label for shelf/bin to map the warehouse. Labels to be defined. This operation could be in arranged by Pansoft.

- Handling unit barcode needs to contain RK header and Equipment id.

- Definition of the rule needed to manage the equipments with multiple boxes

- Need to collect existing Barcode rules to start developing

Master Data info

RK header needs to have the following info:

- Segment (Hips, Knees…)

- Box type (E.g.: Small/Medium/Big)

- Box necessarily to be stored on the floor (e.g. due to weightiness)

Warehouse locations need to have the following info:

- Segment

- Capability in terms of Box type (E.g.: Small/Medium/Big)

- Box necessarily to be stored on the floor

- Indication (Y/N) for the “Floor locations”

- Max number of equipments that can be stored (999999: limitless capability)

Discover other Medcon solutions

MedCon is Pansoft’s WEB-based application that allows to keep under control the Consignment’s flows and processes, satisfying and protecting in a safe and totally transparent way the needings of both the suppliers, owner of the material, and customers (private and public hospitals) that are the end users of all items/lots in Consignment.

The application of the MedCon family that allows Distributors of material in Consignment and for Sale to manage all Logistics processes up to Invoicing.

Pansoft’s Windows platform software for physical inventory operations (both at internal and consignment warehouses) connectable to any customer’s ERP (already integrated with PRMS, SAP, JDE).